Barra de ângulo de canto de aço carbono ASTM de ângulo igual

Detalhes do produto

Cantoneira de aço carbonoAs barras de aço são um tipo comum de aço estrutural usado em diversas aplicações de construção e fabricação. Geralmente são feitas de aço carbono, que oferece boa resistência e conformabilidade. Aqui estão alguns detalhes gerais sobre as barras de aço carbono em ângulo:

MaterialAs cantoneiras de aço carbono são geralmente feitas de aço de baixo carbono, que contém uma pequena quantidade de carbono, tipicamente na faixa de 0,05% a 0,25%. Isso as torna adequadas para soldagem, conformação e usinagem.

FormaAs cantoneiras de aço carbono têm uma seção transversal em forma de L. Elas são formadas pela dobra de uma única peça de aço em um ângulo de 90 graus, resultando em duas abas de comprimento igual ou desigual.

DimensõesAs cantoneiras de aço carbono estão disponíveis em diversas dimensões padrão, incluindo o comprimento das abas, a espessura e a largura (medida da extremidade externa de uma aba até a extremidade externa da outra).

Acabamento da superfíciePodem ser fornecidas com acabamento bruto, que pode apresentar algumas imperfeições na superfície, ou com um acabamento liso e polido.

AplicaçõesAs cantoneiras de aço carbono são comumente usadas em aplicações estruturais e arquitetônicas, incluindo estruturas de edifícios, contraventamento, suportes e reforços. Elas também são usadas em aplicações industriais e em máquinas.

PadrõesAs cantoneiras de aço carbono são fabricadas para atender a diversas normas internacionais, como ASTM, JIS, EN e GB/T.

| Padrão | AISI, ASTM, DIN, GB, JIS, SUS | |||

| Diâmetro | De 2 mm a 400 mm ou de 1/8" a 15" ou conforme a necessidade do cliente. | |||

| Comprimento | De 1 a 6 metros ou conforme a necessidade do cliente. | |||

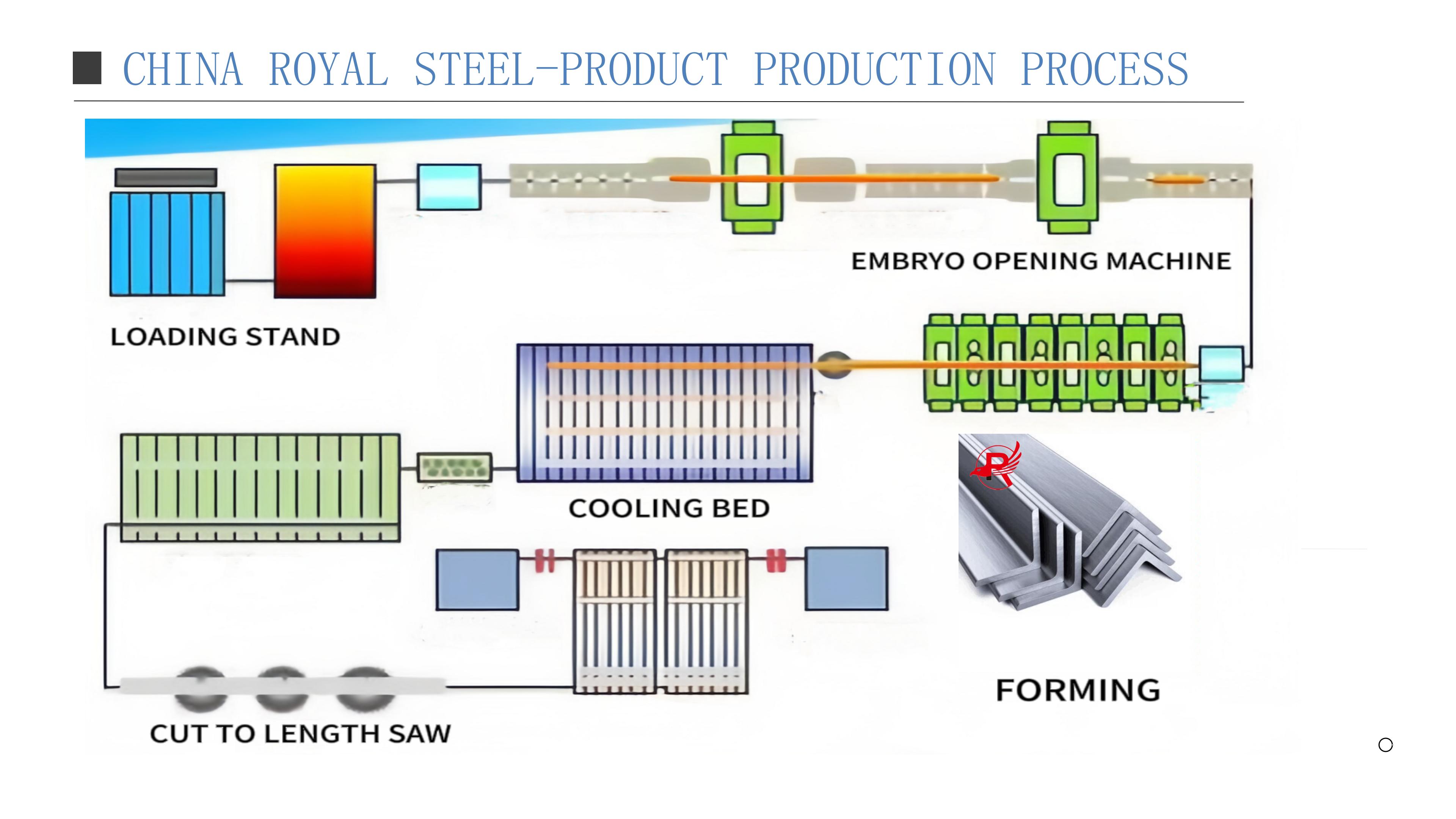

| Tratamento/Técnica | Laminado a quente, trefilado a frio, recozido, moído | |||

| Superfície | Acabamento acetinado, 400#, 600~1000# espelhado, escovado HL, espelhado escovado (dois tipos de acabamento para um tubo) | |||

| Aplicações | Petróleo, eletrônica, química, farmacêutica, têxtil, alimentícia, maquinário, construção, energia nuclear, aeroespacial, militar e outras indústrias | |||

| Termos comerciais | EXW, FOB, CFR, CIF | |||

| Prazo de entrega | Enviado em 7 a 15 dias após o pagamento. | |||

| Pacote | Pacote padrão para transporte marítimo ou conforme necessário. | |||

| EMBALAGEM ADEQUADA PARA VIAGEM MARÍTIMA | Cabine GP de 20 pés: 5,8 m (comprimento) x 2,13 m (largura) x 2,18 m (altura), aproximadamente 24-26 m³ | |||

| Contêiner GP de 40 pés: 11,8 m (comprimento) x 2,13 m (largura) x 2,18 m (altura), aproximadamente 54 m³. Contêiner HG de 40 pés: 11,8 m (comprimento) x 2,13 m (largura) x 2,72 m (altura), aproximadamente 68 m³. | ||||

| Aço de ângulo igual | |||||||

| Tamanho | Peso | Tamanho | Peso | Tamanho | Peso | Tamanho | Peso |

| (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) | (MM) | (KG/M) |

| 20*3 | 0,889 | 56*3 | 2,648 | 80*7 | 8,525 | 12*10 | 19.133 |

| 20*4 | 1,145 | 56*4 | 3,489 | 80*8 | 9,658 | 125*12 | 22,696 |

| 25*3 | 1,124 | 56*5 | 4,337 | 80*10 | 11,874 | 12*14 | 26.193 |

| 25*4 | 1,459 | 56*6 | 5,168 | 90*6 | 8,35 | 140*10 | 21.488 |

| 30*3 | 1,373 | 63*4 | 3,907 | 90*7 | 9,656 | 140*12 | 25.522 |

| 30*4 | 1,786 | 63*5 | 4,822 | 90*8 | 10,946 | 140*14 | 29,49 |

| 36*3 | 1,656 | 63*6 | 5,721 | 90*10 | 13.476 | 140*16 | 33.393 |

| 36*4 | 2,163 | 63*8 | 7,469 | 90*12 | 15,94 | 160*10 | 24.729 |

| 36*5 | 2,654 | 63*10 | 9.151 | 100*6 | 9,366 | 160*12 | 29.391 |

| 40*2,5 | 2.306 | 70*4 | 4,372 | 100*7 | 10,83 | 160*14 | 33,987 |

| 40*3 | 1,852 | 70*5 | 5,697 | 100*8 | 12.276 | 160*16 | 38.518 |

| 40*4 | 2,422 | 70*6 | 6.406 | 100*10 | 15.12 | 180*12 | 33.159 |

| 40*5 | 2,976 | 70*7 | 7,398 | 100*12 | 17.898 | 180*14 | 38.383 |

| 45*3 | 2.088 | 70*8 | 8,373 | 100*14 | 20.611 | 180*16 | 43,542 |

| 45*4 | 2,736 | 75*5 | 5,818 | 100*16 | 23.257 | 180*18 | 48,634 |

| 45*5 | 3,369 | 75*6 | 6,905 | 110*7 | 11.928 | 200*14 | 42,894 |

| 45*6 | 3,985 | 75*7 | 7,976 | 110*8 | 13.532 | 200*16 | 48,68 |

| 50*3 | 2,332 | 75*8 | 9.03 | 110*10 | 16,69 | 200*18 | 54.401 |

| 50*4 | 3.059 | 75*10 | 11.089 | 110*12 | 19.782 | 200*20 | 60.056 |

| 50*5 | 3,77 | 80*5 | 6.211 | 110*14 | 22.809 | 200*24 | 71.168 |

| 50*6 | 4,456 | 80*6 | 7,376 | 125*8 | 15.504 | ||

FormaEssas barras angulares possuem uma seção transversal em forma de L, com duas abas de comprimento igual ou desigual que se encontram em um ângulo de 90 graus. Esse formato as torna adequadas para fornecer suporte estrutural e reforço em diversas aplicações.

Resistência e capacidade de cargaAs cantoneiras de carbono são projetadas para oferecer alta resistência à tração, tornando-as adequadas para suportar cargas pesadas e proporcionar estabilidade estrutural em construções.

VersatilidadeEstão disponíveis em diversas dimensões e espessuras, o que permite versatilidade nas aplicações. Podem ser utilizadas para enquadramento, contraventamento, suportes e como componentes em vários tipos de estruturas.

Resistência à corrosãoDependendo da liga específica e do tratamento de superfície, as barras de aço carbono em ângulo podem oferecer diferentes graus de resistência à corrosão. Um tratamento de superfície ou revestimento adequado pode aumentar sua durabilidade em ambientes corrosivos.

Usinabilidade e soldabilidadeAs barras de aço carbono em ângulo podem ser facilmente usinadas, cortadas e soldadas, permitindo flexibilidade nos processos de fabricação e construção.

Conformidade com as normasEssas barras angulares são normalmente fabricadas para atender aos padrões industriais e internacionais, como ASTM, AISI, DIN, EN e JIS, garantindo que atendam a requisitos mecânicos e dimensionais específicos.

Características

As cantoneiras de aço carbono, também conhecidas como barras de aço carbono em formato de U, são um tipo de componente estrutural de aço usado principalmente na construção civil, manufatura e aplicações industriais. A seguir, algumas características principais das cantoneiras de aço carbono:

MaterialAs cantoneiras de aço carbono são feitas de aço carbono, uma liga de ferro-carbono com uma pequena porcentagem de carbono (normalmente menos de 2%). Esse material oferece boa resistência, durabilidade e soldabilidade.

FormaEssas barras angulares possuem uma seção transversal em forma de L, com duas abas de comprimento igual ou desigual que se encontram em um ângulo de 90 graus. Esse formato as torna adequadas para fornecer suporte estrutural e reforço em diversas aplicações.

Resistência e capacidade de cargaAs cantoneiras de carbono são projetadas para oferecer alta resistência à tração, tornando-as adequadas para suportar cargas pesadas e proporcionar estabilidade estrutural em construções.

VersatilidadeEstão disponíveis em diversas dimensões e espessuras, o que permite versatilidade nas aplicações. Podem ser utilizadas para enquadramento, contraventamento, suportes e como componentes em vários tipos de estruturas.

Resistência à corrosãoDependendo da liga específica e do tratamento de superfície, as barras de aço carbono em ângulo podem oferecer diferentes graus de resistência à corrosão. Um tratamento de superfície ou revestimento adequado pode aumentar sua durabilidade em ambientes corrosivos.

Usinabilidade e soldabilidadeAs barras de aço carbono em ângulo podem ser facilmente usinadas, cortadas e soldadas, permitindo flexibilidade nos processos de fabricação e construção.

Conformidade com as normasEssas barras angulares são normalmente fabricadas para atender aos padrões industriais e internacionais, como ASTM, AISI, DIN, EN e JIS, garantindo que atendam a requisitos mecânicos e dimensionais específicos.

Aplicativo

As cantoneiras de aço macio, também conhecidas como perfis de aço de baixa liga, são comumente usadas em diversas aplicações devido à sua versatilidade e propriedades estruturais. Aqui estão algumas aplicações comuns de cantoneiras de aço macio:

ConstruçãoAs cantoneiras de aço são amplamente utilizadas na construção civil para estruturas, contraventamento e suporte. São comumente usadas na criação de armações para edifícios, pontes e projetos de infraestrutura.

FabricaçãoEssas barras angulares são utilizadas na fabricação de componentes estruturais para máquinas, equipamentos e estruturas industriais. Elas fornecem suporte e reforço cruciais no setor de manufatura.

Design arquitetônico e de interioresEm projetos de arquitetura e design de interiores, as cantoneiras de aço macio são utilizadas para criar estruturas de sustentação, suportes para acessórios e elementos decorativos. Elas podem ser usadas tanto para fins estéticos quanto para suporte estrutural prático.

Prateleiras e estantesAs barras angulares de aço são comumente usadas na construção de estantes, prateleiras de armazenamento e estruturas de armazém devido à sua resistência e capacidade de suportar cargas.

Fabricação de móveisNa indústria moveleira, as cantoneiras de aço macio são utilizadas na construção de armações, estruturas de suporte e suportes para diversos tipos de móveis, incluindo mesas, cadeiras e estantes.

Fabricação de veículos e equipamentosEssas barras angulares são utilizadas na fabricação e reforço de chassis de veículos, reboques e suportes de equipamentos devido à sua resistência e durabilidade.

Aplicações agrícolasNo setor agrícola, as cantoneiras de aço são utilizadas na construção de estruturas agrícolas, suportes para equipamentos e instalações de armazenamento.

projetos faça você mesmoAs cantoneiras de aço macio são frequentemente usadas em projetos do tipo "faça você mesmo" (DIY), incluindo reformas residenciais, construção de estruturas personalizadas e criação de suportes para diversas aplicações.

Embalagem e envio

Aço angularGeralmente, a embalagem é feita de forma adequada ao tamanho e peso do produto durante o transporte. Os métodos de embalagem mais comuns incluem:

Envolvimento: Cantoneiras de aço de menor diâmetro geralmente são envolvidas com fita de aço ou plástico para garantir a segurança e a estabilidade do produto durante o transporte.

Embalagem de cantoneiras de aço galvanizado: No caso de cantoneiras de aço galvanizado, geralmente são utilizados materiais de embalagem impermeáveis e resistentes à umidade, como filme plástico impermeável ou caixa de papelão resistente à umidade, para evitar oxidação e corrosão.

Embalagem de madeira: Cantoneiras de aço de maior tamanho ou peso podem ser embaladas em madeira, como paletes ou caixas de madeira, para proporcionar maior suporte e proteção.

Perguntas frequentes

1. Como posso obter um orçamento de vocês?

Você pode nos deixar uma mensagem e responderemos a todas elas o mais breve possível.

2. Vocês entregarão a mercadoria no prazo?

Sim, prometemos fornecer produtos da melhor qualidade e entrega no prazo. A honestidade é o princípio fundamental da nossa empresa.

3. Posso receber amostras antes de fazer o pedido?

Sim, claro. Normalmente, nossas amostras são gratuitas e podemos produzir com base em suas amostras ou desenhos técnicos.

4. Quais são as suas condições de pagamento?

Nossa forma usual de pagamento é 30% de entrada e o restante contra o conhecimento de embarque (B/L). EXW, FOB, CFR, CIF.

5. Vocês aceitam inspeção por terceiros?

Sim, aceitamos sem dúvida.

6. Como podemos confiar na sua empresa?

Somos especialistas no setor siderúrgico há anos, atuando como fornecedores de ouro. Nossa sede está localizada na província de Tianjin. Entre em contato conosco para mais informações.