Construção de Posto de Gasolina: Estrutura Metálica para Coberturas de Postos de Gasolina

O aço é um corpo elastoplástico ideal, que se conforma plenamente aos métodos de cálculo e conceitos básicos atualmente utilizados. Portanto, o cálculo da construção de estruturas de aço é preciso, seguro e confiável.

*Dependendo da sua aplicação, podemos projetar o sistema de estrutura de aço mais econômico e durável para ajudá-lo a gerar o máximo valor para o seu projeto.

| Nome do produto: | Estrutura metálica de construção em aço |

| Material: | Q235B, Q345B |

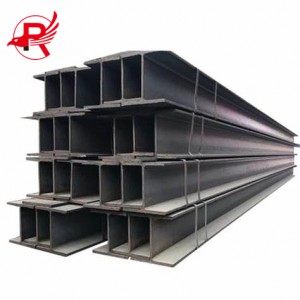

| Quadro principal: | Viga de aço em forma de H |

| Terça: | Terça de aço em forma de C, Z |

| Telhado e parede: | 1. chapa de aço corrugado; 2. Painéis sanduíche de lã de rocha; 3. Painéis sanduíche de EPS; 4. Painéis sanduíche de lã de vidro |

| Porta: | 1. Portão de enrolar 2. Porta de correr |

| Janela: | PVC, aço ou liga de alumínio |

| Calha de descida: | Tubo de PVC redondo |

| Aplicativo : | Todos os tipos de oficinas industriais, armazéns e edifícios altos. |

A produção de estruturas de aço geralmente é realizada por meio de construção mecanizada em fábricas de processamento de estruturas metálicas, com alta precisão e exatidão. Diversos tipos de aço são frequentemente utilizados na produção para acelerar a construção. Os componentes de aço são leves, de fácil e rápida montagem, e o tempo de construção é reduzido.

*Envie o e-mail para[email protected]Para obter um orçamento para seus projetos

PROCESSO DE PRODUÇÃO DO PRODUTO

VANTAGEM

A qualidade do aço estrutural

Existem muitas opções diferentes quando se trata de aço estrutural. Quanto menor o teor de carbono no aço escolhido, mais fácil será a soldagem. Um teor de carbono mais baixo significa uma produção mais rápida em projetos de construção, mas também pode tornar o material mais difícil de trabalhar. A FAMOUS oferece soluções em aço estrutural que são fabricadas com eficiência e são altamente eficazes. Trabalharemos com você para determinar o tipo perfeito de aço estrutural para o seu projeto. Os processos utilizados para projetar aço estrutural podem alterar o custo. No entanto, o aço estrutural é um material com excelente custo-benefício quando usado corretamente. O aço é um material excelente e altamente sustentável, mas é muito mais eficaz nas mãos de engenheiros experientes e bem qualificados que entendem suas propriedades e benefícios potenciais. No geral, o aço oferece inúmeras vantagens para empreiteiros e outros que pretendem utilizá-lo em aplicações industriais. Especialistas descobriram que até mesmo o reforço de edifícios antigos com novos processos de soldagem pode melhorar significativamente a resistência da construção. Imagine os benefícios de usar aço estrutural soldado por especialistas desde o início do seu projeto de construção. Entre em contato com a FAMOUS para todas as suas necessidades de soldagem e fabricação de aço estrutural.

Rigidez suficiente

A rigidez refere-se à capacidade de um elemento de aço resistir à deformação. Se o elemento de aço sofrer deformação excessiva após ser submetido a tensão, ele não funcionará corretamente, mesmo que não tenha sido danificado. Portanto, o elemento de aço deve ter rigidez suficiente, ou seja, não pode apresentar falhas por falta de rigidez. Os requisitos de rigidez variam para diferentes tipos de componentes, e as normas e especificações relevantes devem ser consultadas na aplicação.

Estabilidade

Estabilidade refere-se à capacidade de um componente de aço manter sua forma (estado) de equilíbrio original sob a ação de uma força externa.

A perda de estabilidade é o fenômeno em que o elemento de aço altera repentinamente sua forma de equilíbrio original quando a pressão aumenta até um certo nível, o que é denominado instabilidade. Alguns elementos de paredes finas comprimidos também podem alterar repentinamente sua forma de equilíbrio original e se tornarem instáveis. Portanto, esses componentes de aço devem ser capazes de manter sua forma de equilíbrio original, ou seja, devem possuir estabilidade suficiente para garantir que não se tornem instáveis e danificados sob as condições de uso especificadas.

DEPÓSITO

Nossa empresa exporta com frequência.Aço estrutural para construçãopara as Américas e países do Sudeste Asiático. Participamos de um dos projetos nas Américas, com uma área total de aproximadamente 543.000 metros quadrados e um uso total de cerca de 20.000 toneladas de aço. Após a conclusão do projeto, ele se tornará um complexo de estrutura metálica integrando produção, moradia, escritórios, educação e turismo.

INSPEÇÃO DE PRODUTOS

1) Testes de materiais paraConstrução com estrutura metálica

Materiais estruturais: aço componente, aço nó;

Materiais para conexão: materiais de soldagem ou metal de solda, parafusos, rebites;

Materiais para manutenção ou proteção: revestimento anticorrosivo, revestimento retardante de chamas, proteção de revestimento externo.

(2) Inspeção de componentes estruturais de aço

Os componentes de aço incluem: vigas, colunas, barras, cabos, placas, cascas, treliças e outras unidades de detecção ou cálculo.

(3) Conexão de estrutura de aço e detecção de nós

As conexões incluem: soldas, parafusos de alta resistência, parafusos comuns, pinos, rebites e parafusos;

Os nós incluem: nós viga-coluna, nós viga-viga, nós de apoio, nós de cabo, nós de haste de cabo, nós de apoio e nós de pé da coluna.

(4) Inspeção do sistema de estrutura de aço

A composição do sistema de estrutura de aço e a disposição de seus componentes (incluindo suportes), rotas de transmissão de força e linhas de defesa contra terremotos;

A estrutura dos componentes, nós, suportes e bases das colunas.

(5) Detecção de carga e ação em estruturas de aço

Tipo, distribuição e tamanho das cargas convencionais;

Tipo, distribuição e magnitude das cargas acidentais;

Outros possíveis efeitos e características de distribuição.

(6) Detecção de vibração em estruturas de aço

Características dinâmicas de cargas dinâmicas externas;

características de vibração da estrutura;

Resposta vibratória da estrutura.

PROJETO

Nossa empresa exporta frequentemente produtos de estruturas metálicas para as Américas e países do Sudeste Asiático. Participamos de um projeto nas Américas com uma área total de aproximadamente 543.000 metros quadrados e um consumo total de cerca de 20.000 toneladas de aço. Após a conclusão do projeto, ele se tornará um complexo de estruturas metálicas integrando produção, moradia, escritórios, educação e turismo.

APLICATIVO

Construção de edifícios em açoSão amplamente utilizados nos seguintes campos devido às suas vantagens de leveza, alta resistência, boa plasticidade e curto período de construção:

1. Edifícios altos: As estruturas de aço podem proporcionar soluções de construção mais rápidas, flexíveis e econômicas para edifícios altos. Entre elas, algumas formas especiais de edifícios altos, como estruturas de aço com pórticos metálicos, estruturas suspensas e estruturas em malha, frequentemente utilizam estruturas de aço.

2. Pontes: As pontes com estrutura de aço apresentam características como baixo peso próprio, alta resistência e grandes vãos. Podem ser aplicadas em diversos tipos de terreno e condições climáticas, além de serem altamente controláveis em termos de projeto, fabricação e transporte.

3. Instalações esportivas: As estruturas de aço podem proporcionar melhor suporte e rigidez para grandes instalações esportivas, além de melhorar a resistência sísmica do edifício.

4. Edifício fabril: A estrutura de aço pode proporcionar um espaço maior e melhor iluminação para o edifício fabril, reduzir o peso da construção e encurtar o período de construção.

5. Salão de exposições: A estrutura de aço proporciona ao salão de exposições um espaço maior, um layout mais flexível e um ambiente de visualização mais confortável. Também reduz o peso e o sombreamento do edifício, além de melhorar a iluminação e a ventilação.

Em resumo, as estruturas de aço têm amplas perspectivas de aplicação e importantes significados sociais, econômicos, de proteção ambiental, de segurança e outros. Elas são amplamente utilizadas na construção civil, nos transportes, na indústria e em outros setores.

EMBALAGEM E ENVIO

A embalagem e o transporte deConstrução em açoÉ necessária a atenção deles, o que é muito importante para o transporte. A embalagem deve ser forte e resistente, e o transporte pode ser escolhido entre LCL (carga consolidada), carga a granel, contêineres, frete aéreo, etc. A resistência das estruturas de aço é alta, assim como o módulo de elasticidade. Comparado com o concreto e a madeira, o aço apresenta porosidade e resistência relativamente baixas, portanto, sob as mesmas condições de tensão, a estrutura de aço tem como características seção transversal reduzida, peso reduzido, facilidade de instalação e transporte, sendo adequada para estruturas de grande vão, altura elevada e cargas pesadas.

PONTOS FORTES DA EMPRESA

Fabricado na China, serviço de primeira classe, qualidade de ponta, mundialmente reconhecido.

1. Efeito de escala: Nossa empresa possui uma ampla cadeia de suprimentos e uma grande fábrica de aço, alcançando efeitos de escala no transporte e na aquisição, e se tornando uma siderúrgica que integra produção e serviços.

2. Diversidade de produtos: Oferecemos uma ampla variedade de produtos em aço, incluindo estruturas metálicas, trilhos de aço, estacas-prancha de aço, suportes para painéis fotovoltaicos, perfis U, bobinas de aço silício, entre outros. Isso nos permite oferecer maior flexibilidade na escolha do tipo de produto ideal para atender a diferentes necessidades.

3. Fornecimento estável: Uma linha de produção e uma cadeia de suprimentos mais estáveis podem proporcionar um fornecimento mais confiável. Isso é especialmente importante para compradores que necessitam de grandes quantidades de aço.

4. Influência da marca: Possuir maior influência de marca e um mercado mais amplo.

5. Serviço: Uma grande empresa siderúrgica que integra personalização, transporte e produção.

6. Competitividade de preços: preço razoável

*Envie o e-mail para[email protected]Para obter um orçamento para seus projetos

VISITA DOS CLIENTES